Strenghts

- High time and space optimization

- High performance of picking with goods to the operator

- Storage of small packages

Applications

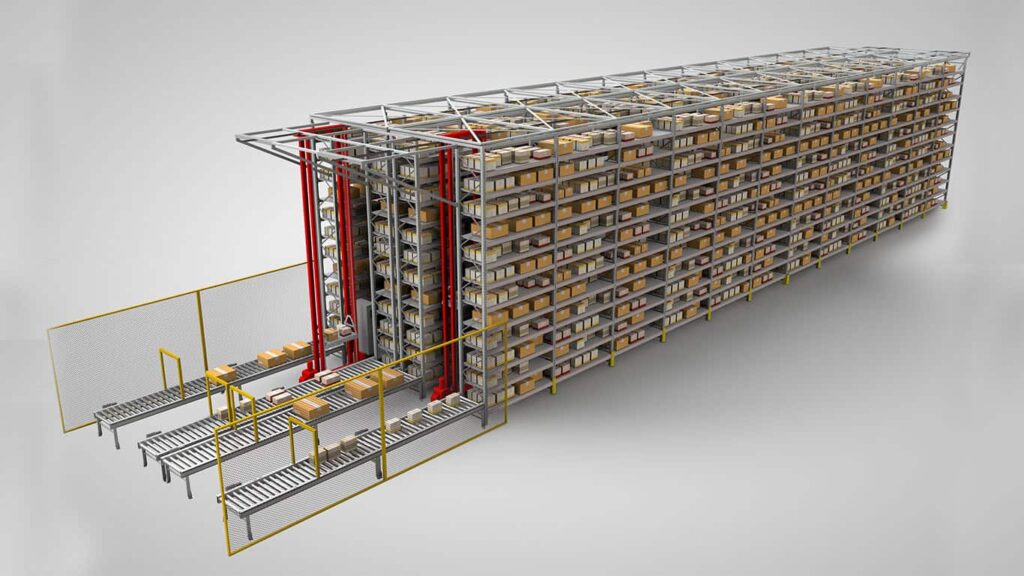

Dalmine LS automatic shelving systems are the most efficient solution to meet today’s market needs. The spread of electronic commerce has placed companies in a multi-faceted situation: growth in the number of references managed, reduction in order processing times, unpredictability of workloads. An automatic warehouse solution with its shelving system can effectively meet these requirements.

More info

An automatic warehouse for boxes and packages is composed of a storage system and automatic handling, the picking zones of the head, the software of management of the warehouse (WMS) and industrial shelving suitably dimensioned and calibrated.

Metal racks are usually higher than traditional warehouses because the picking and storage operations are carried out by special machines (miniload or AMR) that work without the intervention of operators. The racks can be configured with single, double or multiple depth, according to the logistic needs of the company.

Automatic storage systems for boxes and packages guarantee an overall optimization of the storage processes, increasing productivity and eliminating errors related to manual handling. In fact, the automatic warehouses work according to precise and pre-ordered sequences, thanks to the WMS settings.

The advantages of using Dalmine LS storage racks are various:

- Complete automation of all storage and picking of boxes and packages;

- Fast operations: thanks to the automatic warehouse racking, the picking frequency can be up to five times higher than a traditional solution. As a result, order processing times are shortened and handling capacity and productivity is increased;

- More precise operations: automation of the logistics chain eliminates errors linked to manual handling processes;

- Vertical development and optimization of the space in the plan, with the possibility of reducing the occupied surface up to ten times at equal capacity, thanks to the compactness of the structure and the possibility of storage in single, double or multiple depth;

- Efficient package management;

- Reliable tracking and efficient management of stock through a constantly updated inventory;

- Increased safety as operators must not enter the warehouse;

- Short time ROI and overall cost reduction.

For any further information and to receive any case history on this type of shelving, please contact our offices: we will be happy to inform you.

3D Model

Gallery