Strenghts

- Optimization of time and space

- Reduction of internal routes

- High picking with dedicated solutions

- Storage of small parcels

- High speed and high number of processing order rows

Applications

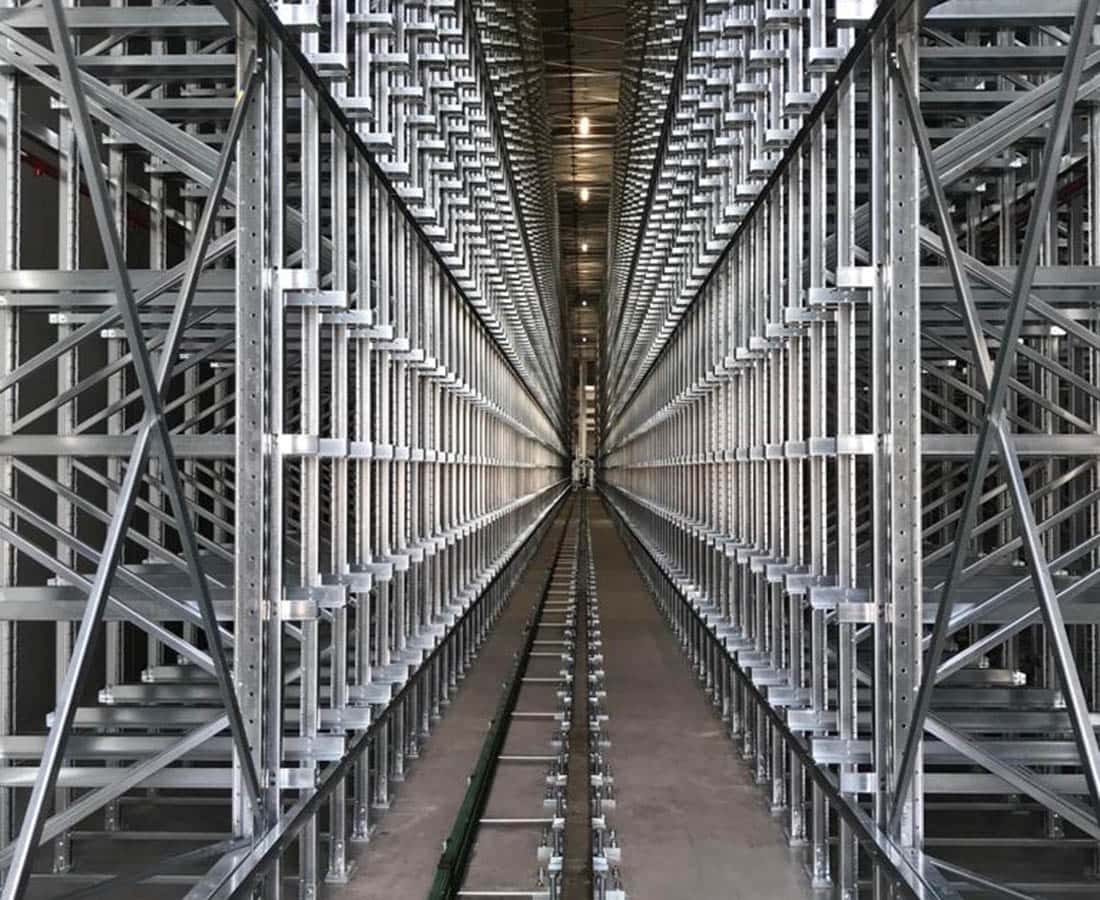

Automation in the picking processes allows to use storage facilities with continuous operation, according to the principle of goods-to-person, obtaining a reduction in internal routes. In fact, items are delivered directly to the picking stations ensuring high safety standards for pickers and avoiding travel. This way the hourly performance is greatly increased.

More info

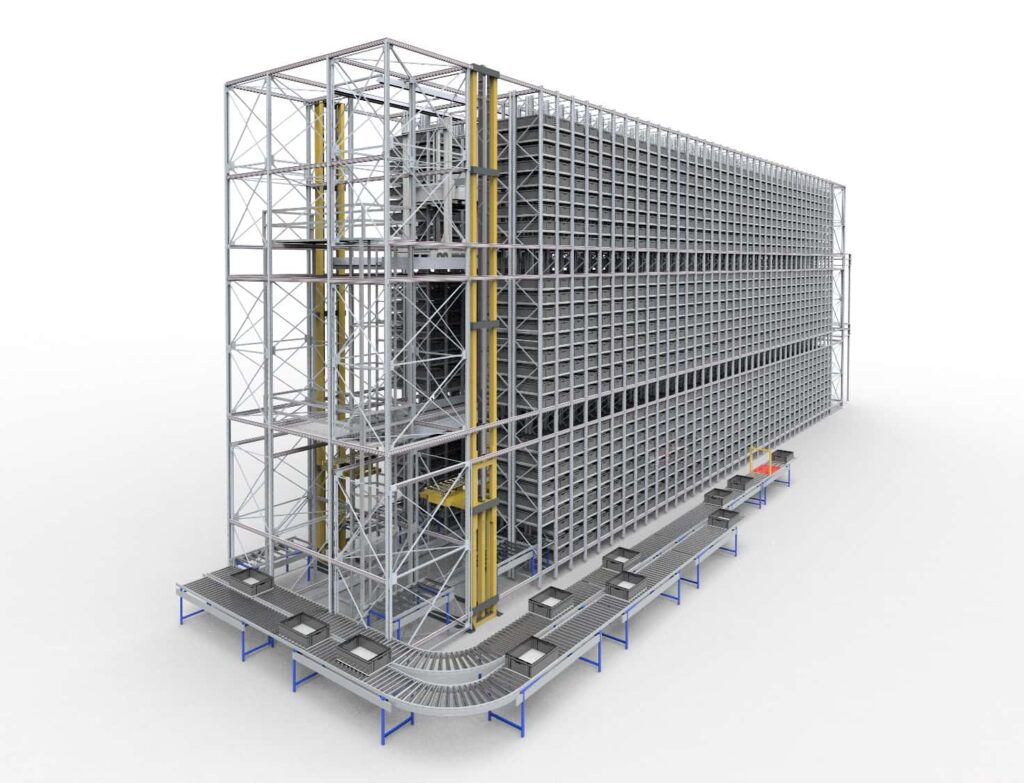

The perfect solution for today’s market demands that require ever higher performance

of picking: large numbers of orders with few processed pieces and processed in ever shorter times.

With the automation system for packages you have a complete visibility on stock and cycles In/ Out.

Automation in the picking processes allows to use storage facilities with continuous operation, according to the principle of goods-to-person, obtaining a reduction in internal routes. In fact, items are delivered directly to the picking stations ensuring high safety standards for pickers and avoiding travel. This way the hourly performance is greatly increased.

- The height of our shelving is limited exclusively by the building, in fact thanks to our production capacity we can reach 45 meters.

- Our shelving systems can be integrated with the different automation systems: miniload, skypod, shuttle

- The automatic solution can be integrated with the various pick to light and pull to light systems

- The shelf or rack configuration allows for the storage of a wide range of load units

- Single, double or multiple depth storage options

3D Model

Gallery